The linear motion and high force produced by hydraulic cylinders are big reasons why designers specify hydraulic and pneumatic systems in the first place.

The Basics

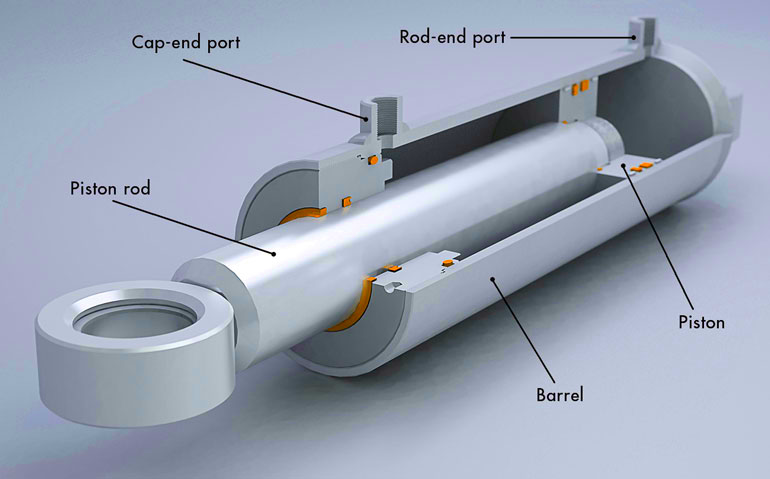

The most common hydraulic cylinder configuration is double acting . Routing pressurized fluid into the rod end of a double-acting cylinder causes the piston rod to retract. Conversely, routing pressurized fluid into the cap end causes the rod to extend. Simultaneously, fluid on the opposite side of the piston flows back into the hydraulic reservoir.

1. Cutaway view shows key features of a typical cylinder—in this case, a double-acting welded design for hydraulic service.

Because the area of the rod-end piston face is smaller than the cap-end area, extension force is greater than retraction force (assuming equal fluid pressures). Because total cylinder volume is less with the piston rod fully retracted (because of rod volume) than when it is fully extended, a cylinder retracts faster than it extends (assuming equal flow rates).

Single-acting cylinders accept pressurized fluid on only one side of the piston; volume on the other side of the piston is vented to atmosphere or returns to tank. Depending on whether it is routed to the cap end or rod end, the pressurized fluid may extend or retract the cylinder, respectively. In either case, force generated by gravity or a spring returns the piston rod to its original state. A hydraulic jack for vehicles represents a common application of a single-acting, gravity-return cylinder.

Standard Configurations

Construction variations for single- and double-acting cylinders are based primarily on how the two end caps are attached to the barrel. Additional variations include wall thickness of the barrel and end caps, and materials of construction.

Tie-rod cylinders have square or rectangular end caps secured to each end of the barrel by rods that pass through holes in the corners of the end caps. Nuts threaded onto the end of each tie rod secure the end caps to the barrel. Static seals in the barrel/end-cap interface prevent leakage. A number of variations to this design exist, including use of more than four tie rods on a cylinder, or long bolts that thread into tapped holes in one of the end caps.

2. Tie-rod cylinders are the most widely used design in all of fluid power: industrial and mobile hydraulics and pneumatics. Industry standards exist for basic design, but many variations often applied to make tie-rod cylinders lighter or more compact, or provide other benefits.

Welded cylinders have end flanges welded to the barrel and an end cap attached to each flange. End caps are secured in place by bolts that slip through holes in each end cap and thread into tapped holes in each end flange. This construction is lighter and more compact than the standard tie-rod configuration, which explains why welded cylinders find wide application in mobile equipment.

A variation to this construction has each end cap threaded into the end of the barrel. This construction, however, usually cannot accommodate as high a pressure rating as welded and can be more difficult to disassemble and reassemble.

Mill-duty cylinders have flanges welded to the ends of the cylinder barrels with end caps of the same diameter as the flanges. Bolts secure the end caps to the flanges. Their construction is similar to that of welded cylinders, but mill-duty cylinders have thicker barrel walls and heavier construction in general.

3. Mill-duty cylinders have flanges welded to both ends of their barrel with an end cap bolted to each flange.

Large mill-duty cylinders often have a barrel wall thick enough for the end cap bolts to be threaded directly into the barrel wall. As the name implies, these cylinders were originally de-signed for use in steel mills, foundries, and other severe-duty applications.

4. Double-rod cylinders have a piston rod that extends from both ends of the cylinder. This allows moving a load from either or both ends and also eliminates the issues of differential piston areas inherent to standard single-rod cylinders.

5. Telescopic cylinders have two or more stages that, when fully extended, can produce a stroke that exceeds the length of the cylinder when fully retracted.

Ram cylinders are a special type of single-acting cylinder that has a rod diameter the same as the piston. Used mostly for jacking purposes, ram cylinders must be single acting because there is no internal cylinder volume to pressurize for retracting the rod. Ram cylinders sometimes are called plunger cylinders and are most often used for short-stroke applications. Most do not use return springs, but rather, gravity or the load to retract the piston rod.